These days, supply chain disruptions aren’t just about port closures or bridge collapses or even severe weather events. Sometimes, the disruptions are merely just about the technologies themselves disrupting the way companies move product from Point A to Point B.

It’s these disruptive technologies that are altering the way organizations do business. They’re creating alternative means of connecting data, providing visibility, enforcing safety and more.

Case in point: Emerging technologies are reshaping the future of supply chain.

In fact, the growth of adoption of emerging technologies can be attributed to several key factors, according to ChatGTP -- a disruptive solution in and of itself:

1. Increased efficiency and productivity

2. Cost reduction

3. Competitive advantage

4. Data-driven insights

5. Scalability and flexibility

6. Enhanced customer experience

7. Regulatory compliance and risk management

8. Globalization and remote work

But many experts cite Internet of Things (IoT) as the most promising emerging technology solution for the cold food chain.

“The growth in IoT availability, as well as AI becoming more accessible, has improved a lot over the last few years. However, now the biggest challenge is getting manufacturers and their workforces to select the most scalable and accurate technologies for specific business goals like boosting productivity, efficiency, sustainability, upskilling, etc.,” says James Newman, head of product and portfolio marketing at Augury. “Let’s examine productivity first. Productivity in the manufacturing industry is flat, at best, and rapidly declining, at worst, so what’s been done in terms of technology adoption up until now hasn’t helped enough. Organizations are looking for new ways to solve productivity challenges, and those are being compounded by the silver tsunami, or aging workforce. People with several decades of experience are retiring and workers with limited experience are joining. Now, manufacturers are wondering: how can they empower workers with 2-3 years of experience to operate like veterans with 25-30? The answer: adopt technology that works as an AI co-pilot. Plant teams can cut back on menial tasks because it will be easier to identify production issues like machines that need repairs or processes that happen outside of a desired range. By getting the insights they need to take quicker actions, workers can focus on higher-level tasks and decisions.”

Likewise, companies are focused on enhancing efficiency, reducing costs, optimizing supply chains and minimizing food waste, and emerging technologies like IoT, real-time monitoring and predictive analytics are transforming the food industry, according to Matt Mathai, associate director, professional services and customer experience, Sensitech.

The real-time IoT solution empowers customers to take control of their outbound logistics through streamlined operations and reduced risk with vehicle-agnostic, self-deploying technology.Sensitech

The real-time IoT solution empowers customers to take control of their outbound logistics through streamlined operations and reduced risk with vehicle-agnostic, self-deploying technology.Sensitech

“These tools enable improved traceability, transparency and real-time decision-making throughout the supply chain. The result? Enhanced quality control, reduced waste and a more robust food system,” Mathai adds. “For the food industry, success hinges on the ability of these emerging solutions to address real-world challenges. These challenges include supply chain blind spots, labor shortages, food waste, rising costs and inflexible processes. Technologies offering immediate results with a clear path for continuous improvement will have the greatest impact.”

Digitalization is also critical for tracking data, gaining insights and executing on performance.

“All too often business leaders have relied on out-of-date supply chain strategies and legacy technologies, leaving them blind to the magnitude of risk hiding in their third-party relationships. These risks can look like single-source dependencies, cybersecurity vulnerabilities, reputational risks, and geopolitical disruption, all of which can impact a business's bottom line. So, by necessity, business leaders are now addressing these issues head-on with emerging technologies and data-driven workflows that provide better visibility into the business practices of their supply chain partners,” says Nari Viswanathan, senior director supply chain strategy, Coupa. “Digitization has been critical for gaining these valuable insights. Through automation, digital tools, and new technologies like AI and digital twins, businesses can rethink how and where they produce and source from and better predict impactful events like droughts and flooding. While this does not eliminate risk altogether, improved scenario planning can reduce potential delays, lost revenues, expedited costs, and constant fire drills, which helps them better future-proof their supply chain.”

What’s more, innovations that combine proven technologies with rapid and cost-effective deployment to solve pressing business issues are driving adoption across the supply chain, says Owen Nicholson, CEO, Slamcore. CLICK HERE to read an exclusive interview with Nicholson.

“For example, taking cutting-edge visual spatial intelligence developed for autonomous robots and retrofitting it to intralogistics vehicles delivers immediate gains in availability of accurate, real-time data to integrate into existing real-time location systems. Adding these modules to existing fleet vehicles addresses real-world business issues from scarcity of labor to productivity and efficiency enhancement, all of which establish compelling business cases for technological adoption,” adds Nicholson.

New advancements in emerging tech

To keep up with the ever-changing pace of the supply chain industry, manufacturers are developing solutions that leverage artificial intelligence (AI) to monitor temperature, streamline operations, automate manual processes and better translate data.

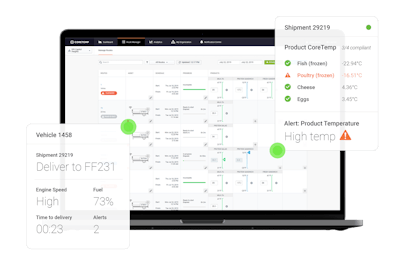

For example, EROAD continues to make significant developments to CoreTemp, which monitors core product temperatures and uses AI to drive actionable insights like early multi-layered temperature warnings, alerts per compartment, real-time route breakdowns, and performance scores.

EROAD's CoreTemp monitors core product temperatures and uses AI to drive actionable insights.EROAD

EROAD's CoreTemp monitors core product temperatures and uses AI to drive actionable insights.EROAD

“These advancements are disrupting how some of the largest North American brands are improving operational practices, quality standards, and minimizing product loss and damage,” says Travis Ross, solutions manager, cold chain and reefer, EROAD. “Our predictive reefer shutdown solution, powered by machine learning, continues to advance significantly, providing carriers with precise insights into the future condition of their refrigerated trailers over the next seven days. These insights are derived from a comprehensive analysis of alarm history, utilization data, and other relevant factors, progressing our ongoing mission to enable carriers to operate their fleets with optimal efficiency.”

EROAD also announced plans to develop new products and features using Microsoft’s generative AI to deliver innovative user experiences.

“Our predictive reefer shutdown solution, powered by machine learning, continues to advance significantly, providing carriers with precise insights into the future condition of their refrigerated trailers over the next seven days. These insights are derived from a comprehensive analysis of alarm history, utilization data, and other relevant factors, progressing our ongoing mission to enable carriers to operate their fleets with optimal efficiency,” adds Ross. CLICK HERE to read our exclusive interview with Ross.

Augury partnered with DSV to introduce a new Parts-as-a-Service (Paas) solution that uses machine health for critical maintenance, repair, and operations production parts and equipment management based on real-time predictive maintenance insights.

“Now manufacturers can order parts when and where they need them, significantly reducing unplanned downtime and inventory carrying costs. With real-time machine insights and DSV’s inventory management solutions, manufacturers can stop buying a surplus of parts or waiting to buy parts after failures happen with all the risk that entails,” Newman says.

Augury also partnered with HSB to expand its Guaranteed Diagnostics to include a production loss guarantee that protects manufacturers from unexpected downtime and production loss due to machine health events not detected by Augury.

“Deploying these emerging technologies allows manufacturers to gain real-time insights that can help them avoid waste that comes from machine malfunctions or process errors, which in turn helps reduce carbon emissions and improve worker safety,” he adds.

For its part, Grip launched a first-of-its-kind order management system specifically focused on perishable direct-to-consumer (DTC). Powered by Grip’s shipping engine, which uses AI to decide the best way to send a box of refrigerated or frozen goods from Point A to Point B, “this technology was inspired by my time as head of logistics for frozen meat delivery subscription ButcherBox,” says Juan Meisel, CEO and co-founder of Grip. “I saw how we were spending millions of dollars a year trying to customize and run software for our logistics operation. I realized there was a huge gap in the market for software tailored to the unique challenges of shipping perishable products nationwide. Our logistics engine analyzes factors such as temperature, major weather events, and carrier performance to provide package-by-package shipping recommendations. This level of insight was previously unattainable for most DTC brands due to resource constraints. We’ve also introduced large language models (LLMs) for internal and external data querying that allows us to service our clients better. You can essentially ask our OMS very complex data or logistics questions in natural language that allows us and our clients to understand our businesses better.” CLICK HERE to read an exclusive interview with Meisel.

In 2023, KNAPP’s first frozen shuttle installation went live at Shufersal in Israel. Operating down to -18°F, the operation allows for frozen “each picking” to support Shufersal’s digital e-commerce operation.

KNAPP commissioned a mixed load palletizing solution at the Kroger Great Lakes distribution center, which included pallet AS/RS, shuttles, conveyor, KiSoft Genomix, KiSoft WCS and a high velocity palletizing solution.KNAPP

KNAPP commissioned a mixed load palletizing solution at the Kroger Great Lakes distribution center, which included pallet AS/RS, shuttles, conveyor, KiSoft Genomix, KiSoft WCS and a high velocity palletizing solution.KNAPP

Earlier this year, KNAPP commissioned a comprehensive, multi-phase, mixed load palletizing solution at the Kroger Grand Lakes facility to include pallet AS/RS, shuttles, conveyor, KiSoft Genomix, KiSoft WCS and a high-velocity palletizing solution that allows Kroger to consolidate warehouse operations, reduce space used and deliver store-friendly pallets.

KNAPP also introduced Genomix to help fight the challenge of incomplete master data.

"Working closely with GS1, Genomix helps clients rapidly and cost effectively build a stronger quality of SKU dimensions and packaging characteristics (up to 60 elements). This helps ensure that SKUs that are not deemed 'automation friendly' are removed in order to avoid impacts to system performance," says Greg Lary, senior systems manager, KNAPP Inc. CLICK HERE to read an exclusive interview with Lary.

Also last year, Sensitech launched a new offering for monitoring outbound shipments through the SensiWatch platform. The real-time IoT solution empowers customers to take control of their outbound logistics through streamlined operations and reduced risk with vehicle-agnostic, self-deploying technology. Automated data capture and monitoring captures critical data throughout the delivery journey, including route optimization, product monitoring and real-time alerts. And end-to-end visibility and temperature control promptly address temperature deviations to optimize operational efficiency and minimize product spoilage.

“As the food industry becomes increasingly globalized, companies are seeking a competitive edge through technology. By leveraging these tools, they can differentiate their products, ensure superior quality and elevate the customer experience, ultimately staying ahead of the curve,” says Mathai.

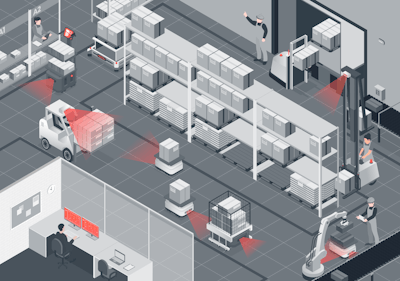

Slamcore Aware packages cutting-edge visual spatial intelligence in a module that can be quickly and easily retrofitted to existing intralogistics vehicles.Slamcore

Slamcore Aware packages cutting-edge visual spatial intelligence in a module that can be quickly and easily retrofitted to existing intralogistics vehicles.Slamcore

In March, Slamcore introduced Slamcore Aware, which packages cutting-edge visual spatial intelligence in a module that can be quickly and easily retrofitted to existing intralogistics vehicles.

“Giving manually driven vehicles the ability to ‘see’ and map the space around them creates highly accurate, real-time spatial data that provides for better route-planning, task allocation, vehicle location and safety features. As a technology that scales with the number of vehicles rather than the size of the facility, and which requires virtually no external additional infrastructure, Slamcore Aware is highly suited to large-scale, dynamic warehouse and factory settings,” adds Nicholson.

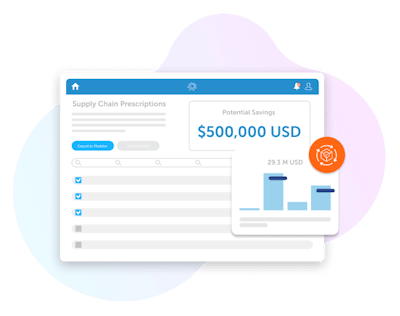

And, this summer, Coupa will launch Forecast Collaboration, which streamlines communication between buyers and suppliers to better match supply and demand.

“Coupa has been leveraging AI for more than a decade and recently announced additional AI-driven automations that will support businesses by increasing payment automation, optimizing collaborative workflow processes, and creating deeper optimization capabilities. These new offerings help companies make smarter, more strategic decisions to improve business decisions and collaboration across the supply chain,” says Viswanathan. CLICK HERE to read an exclusive interview with Viswanathan.

What’s next?

For many companies, stepping out into the wilderness of selecting the right solution for your business can be daunting. Where to start? How to start? How do you know what solution is the best fit for your operation?

Sometimes it’s as simple as identifying the problem and then implementing the solution to fix it.

“Once a clear problem is identified, the next step is identifying the technology and the provider who can support your mission. There are too many industrial tech providers to count; you have to figure out which vendors can move the needle for your company and which vendors are just pushing marketing jargon. In the case of AI, when exploring a new solution, look at the algorithms and understand if they are built to do the job they are designed to do. Are they being continually re-trained across a large dataset, or are they custom-built for your limited dataset? It’s also important to poke holes in a vendor’s pitch. For example, if a company’s sales team claims an impressive stat about their accuracy - ask them to prove it,” says Newman.

Other times, this process involves the need to cultivate a willingness to delve into the operational details and be patient with the process.

“While technology generates data that may initially reveal challenges, that data is always actionable, offering opportunities for significant improvements to profit and loss. Once willingness is established, it’s crucial to invest time in researching the best industry partners who can assist in optimizing key performance indicators (KPIs) related to cold chain,” says Ross.

Regardless of your current supply chain maturity level, gaining real-time visibility into your operations is the first crucial step, advises Mathai.

“Solutions that identify problem areas are the foundation for improvement. From there, organizations can leverage advanced analytics to drive operational transformations. Once on the path, we've seen customers continuously build upon their digital capabilities so they can better leverage tools like AI to drive growth and cost savings,” he adds.

Supply chain leaders and operators should also look at pain points, inefficiencies, and potential areas of improvement.

“Companies should not only ask themselves what they need to improve on, but also get feedback from suppliers on where they think a breakdown is happening,” says Viswanathan. “Some of the most impactful technologies for supply chains are business spend management software for improved transactions and supplier management, supply chain network design for managing constantly evolving supply-demand networks, IoT for real-time tracking and monitoring, and AI for predictive analytics. Ultimately, companies should prioritize technologies that align with their strategic objectives, offer tangible benefits, and demonstrate a clear return on investment for their supply chain operations.”

This summer, Coupa will launch Forecast Collaboration, which streamlines communication between buyers and suppliers to better match supply and demand.Coupa

This summer, Coupa will launch Forecast Collaboration, which streamlines communication between buyers and suppliers to better match supply and demand.Coupa

But, what really is next? How will emerging technologies continue to reshape the cold food chain?

For starters, “the demand for increased visibility and transparency in food quality is only growing stronger – from consumers to production. Therefore, now is a great time to explore and embrace these emerging technologies and their potential benefits for the business,” says Ross.

The increasing preference toward fresh and perishable commodities continues to result in a sharp increase in the cold chain solutions needed to protect temperature-controlled products.

"Accompanying this is the growth in demand for 'ready-to-cook' convenience meals. These market drivers have a direct effect on the need for emerging technologies and will result in faster adoption of new technology. We would expect a spike of investments into software and mechanics that can exist in a sub-freezing temperatures to help alleviate the labor void in this environment” says Lary.

Stockpiling and “just-in-case” inventory systems may always continue to be a “thing” in the grocery retail space.

“This is where AI and digital twin technology are going to be important, especially as we continue to see global warming have an impact on the food supply chain, something we’ve already witnessed in the dairy industry with a butter shortage last year,” says Viswanathan. “These technologies offer digital replicas of the physical supply chain that can help test scenarios and prevent disruption. While these technologies can’t prevent risk, they can allow businesses to plan around disruption and create solutions faster.”

And, getting goods in and out of facilities on time, every time is critical.

“But these facilities are also constantly changing. Internal layouts expand, change, and are reorganized with accelerating regularity. Whatever technological systems you deploy must be flexible enough to cope with this constant change,” says Nicholson.

To put it simply, emerging technologies accelerate innovation because it allows companies to move faster with more data, says Meisel.

“It increases the accuracy rate of decision making which allows the industry to reduce waste and service customers better,” he adds.

Oftentimes a supply chain disruption centers around an event, but sometimes, it also stems from the emerging technologies taking the cold food chain by storm, leveraging AI and IoT to mitigate risk, streamline operations, automate processes and more.

Note from the editor: Parts of the article, including sidebars, were written by ChatGTP and sourced as such. The use of ChatGTP in this article or any article published by Food Logistics is not common practice but was merely an add-on to the emerging technology conversation.