![2024 Top Software Color[vertical]](https://img.foodlogistics.com/files/base/acbm/scn/image/2024/10/2024_Top_Software___color_vertical_.6705637b3b03c.png?auto=format%2Ccompress&q=70&w=400)

From robotics and warehouse automation to procurement and enterprise resource (ERP) software, warehouse management systems (WMS), transportation management systems (TMS) and supply chain visibility solutions, the supply chain software and technology sector continues to boom.

Case in point: By 2026, 30% of enterprises will automate more than half of their network activities, an increase from under 10% in mid-2023, according to Gartner, Inc. And, composite artificial intelligence (AI) and supply chain data governance are the highest impact technology trends for supply chain planning leaders, as outlined in a separate Gartner report.

Additionally, more than three-fourths (83%) of industrial leaders are investing more in AI in 2024, up from 63% in 2023, according to an Augury study. AI aside, other emerging technologies and solutions continue to modernize many of today's supply chains.

So, it's no surprise then that automation, sustainability, smart technology, supply chain optimization and risk management were the major themes of this year’s Top Software & Tech award, presented by Food Logistics and Supply & Demand Chain Executive.

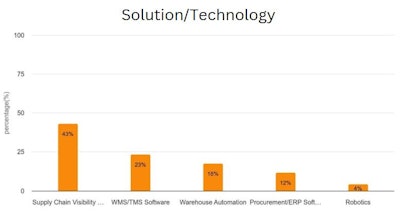

Close to 43% of submissions to this year's Top Software & Tech award pertained to supply chain visibility solutions, followed by WMS/TMS software (23%), warehouse automation (18%), procurement/ERP software (12%) and robotics at just 4% of the submissions.

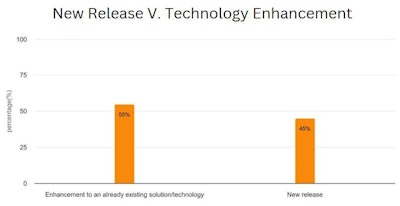

Fifty-five percent of the entries were enhancements to already existing solutions, where 45% came are new-to-market technologies. Further, 58% of submissions came from small businesses, under $50 million, and 42% came from Enterprises, over $50 million.

This award is designed to showcase new-to-market and enhancements to existing software and technology solutions that provide automation, efficiency and visibility to the supply chain space. The new software/technology solution must have been introduced or gone through a major update between October 2023 to September 2024.

These new products and enhancements are upping the ante in modernizing how product moves through the chain.

CLICK HERE to learn more about all of our winners.

Below are the five overall winners.

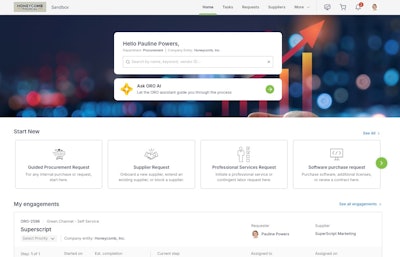

PROCUREMENT/ERP SOFTWARE

ORO Labs

ORO Labs

ORO Labs

www.orolabs.ai

Name of Solution/Technology: ORO Labs Procurement Orchestration Platform

Product Description: ORO Labs launched several enhancements to its procurement orchestration platform that leverage the latest advancements in GenAI to focus on simplifying the procurement intake process. The new GenAI-powered features employ natural language understanding and predictive analytics to enhance the user experience by enabling increased simplicity and efficiency. Additional new features include:

Intent detection. When a user submits a request in natural language, ORO is able to determine a user’s intent and provide the most appropriate response, like initiating the most relevant workflow, providing a status update, or answering a question.

Category recommendations. Business users are often asked to categorize their requests according to the organization’s complex category tree. ORO is able to automatically map a natural language requisition to the correct category.

Buying channel guidance. ORO considers intent and category alongside things like role, region, and company policies in order to determine the best and most efficient buying channel for a particular request. The result is a vastly improved and dynamic user experience, faster processing, and less manual effort.

Supplier recommendation. ORO looks at a company’s preferred supplier list, past transactions, and performance data to suggest the best supplier(s) for a given use case. By doing this, ORO simplifies the selection process, minimizes the need to onboard and maintain new suppliers, and speeds up the requisition-to-pay process.

Smart PO/PR creation. ORO is able to create purchase requisitions and purchase orders by extracting key information from contracts and proposals, The result is a single or multi-line PR/PO that complies with business rules (i.e. CapEx, OpEx, Time-based).

Smart proposal reviews. ORO extracts data from vendor proposals and checks to ensure consistency with the buyer’s intent, buying channel, and category. Ultimately, each element of these new GenAI features works seamlessly to guide users through the end-to-end procurement process without the need for prior knowledge of internal company policies or procedures.

ROBOTICS

Torc Robotics

Torc Robotics

https://torc.ai/

Name of Solution/Technology: Torc Robotics Virtual Driver

Product Description: Torc’s Virtual Driver is designed for commercialization based on its singular, foundational knowledge of trucking companies' complexities and needs. Torc collaborated with Aeva and others for sensors, Foretellix for virtual verification and validation and several additional partners, including Algolux, which Torc acquired in 2023, to integrate cameras, long and short-range LiDAR, and long and short-range radar to detect its surroundings. This sensor suite uses each component’s strengths to provide a 3D picture of the environment, detect objects, and calculate the movement of vehicles around the truck for better prediction and decision-making. Torc’s advanced localization and prediction algorithms provide autonomous trucks with the data to determine the next safe move on busy and unpredictable roadways by planning and updating the truck's location in real-time. Torc’s Virtual Driver also embeds safety into every aspect of its technology—aligning with USDOT and NTSB principles, creating a safer and more reliable ecosystem for transporting goods. These abilities transform off-the-shelf driver assist technology into true autonomy.

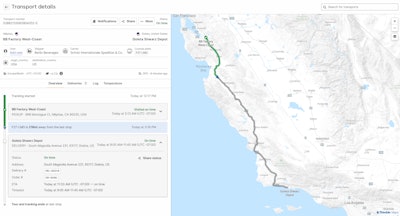

SUPPLY CHAIN VISIBILITY SOLUTIONS

Trimble

Trimble

Trimble

www.transportation.trimble.com

Name of Solution/Technology: Transporeon Visibility

Product Description: Transporeon Visibility is a state-of-the-art real-time transportation visibility solution designed to enhance the efficiency, security, and customer service of logistics operations across various transportation modes, including road, ocean, and air. This solution leverages advanced AI capabilities to provide precise shipment ETAs and integrates seamlessly with Trimble transportation management software (TMS) applications and other visibility solutions. Key features and capabilities include:

Global end-to-end visibility. Comprehensive real-time visibility for all in-transit shipments across all modes of transport up to SKU (order item) level.

Real-time freight tracking. Live tracking and map display of vehicles and shipments, giving operators and stakeholders full control over their shipments. This real-time tracking helps eliminate delays caused by faulty addresses or vehicle license plates.

Accurate ETA predictions. Reliable estimated ETA predictions allow planners and operators to stay ahead of disruptions and proactively manage exceptions with automated triggers and customized sets of rules. This leads to cost savings by reducing demurrage and detention penalties, and optimizing the deployment of equipment and driver resources.

Data sharing and security. The solution ensures data security by sharing data only when consent is given, a vehicle is allocated, and data sharing criteria are met. This feature is particularly attractive for smaller carriers that need to use a single visibility tool regardless of multiple shippers’ requirements.

Wider business opportunities. Facilitates the expansion of carrier networks for shippers and provides visibility into the performance of those carriers. Brokers and carriers can manage subcontractor performance more efficiently.

Security and safety. Real-time visibility enables precise monitoring of shipment routing and location, addressing unexpected deviations and efficient resource allocation quickly.

Interconnected transportation modes. The solution covers intermodal visibility, including changeover points such as ports and airports where disruptions are more likely to occur. This visibility extends to intercompany flows when shipments transfer from one carrier to another.

Integration and deployment. Transporeon Visibility integrates seamlessly with Trimble TMS products such as TMW.Suite and Innovative, with additional integrations like TruckMate expected by the end of the year. This seamless integration allows carriers to automate their data sharing and network connectivity. Enhanced efficiency. By automating transport processes and providing actionable analytics, Transporeon Visibility helps companies improve their logistics operations. The solution offers the highest ETA accuracy in the market, reducing check calls by up to 80% and increasing sales revenue by up to 2%. Sustainability. The solution helps reduce empty miles by up to 10% and CO2 emissions by up to 7%, contributing to more sustainable logistics operations.

Customer satisfaction. Real-time visibility improves customer satisfaction by enabling better communication and proactive problem management. Customized notifications keep all stakeholders informed about the status and progress of shipments.

Improved on-time delivery. Accurate ETAs empower users to better predict and anticipate in-transit issues, enabling proactive transport management by exception.

WAREHOUSE AUTOMATION

ArcBest

ArcBest

ArcBest

www.arcb.com

Name of Solution/Technology: Vaux Smart Autonomy

Product Description: Vaux Smart Autonomy is autonomous material handling technology that combines autonomous mobile robot (AMR) forklifts and reach trucks, intelligent fleet management software and remote teleoperation capabilities to autonomously handle materials movement within warehouses, distribution centers and manufacturing facilities while keeping humans in the loop for the edge cases. Here’s how it works:

1. WMS dispatches work to fleet management software.

2. Fleet management directs the vehicle to drive autonomously to a pickup destination.

3. Teleoperator is assigned a mission to pick materials.

4. Autonomy takes over, and the forklift self-navigates to the destination.

5. Teleoperator is assigned a mission to drop materials.

6. All while the teleoperator works from anywhere in the world.

The forklifts and reach trucks move independently within the warehouse while teleoperators monitor and operate multiple vehicles in multiple locations from a remote location. Operators only have to step in when an AMR encounters a problem the autonomy can’t solve, or it reaches its destination. Vaux Smart Autonomy reduces operational errors, enables more consistency in customers’ businesses, makes processes more efficient and creates a safer environment for people and products. The counterbalance forklift is used for trailer load and unload, cross-warehouse transfer and bulk storage, while the reach truck is used for rack pick and put away. Both forklifts and reach trucks are equipped with advanced software, sensors and cameras that help the robots safely navigate warehouse facilities and create efficiencies in warehouse operations. A teleoperator center complements the autonomous vehicles by remotely monitoring many autonomous robots simultaneously and stepping in to operate remotely when the autonomy needs human assistance. Vaux Smart Autonomy uses state-of-the-art 3D perception technology to perceive its environment and optimize path planning in real time. Additional capabilities include advanced 2D barcoding functionality, cameras with barcode scanning capabilities and easy integration with customers’ WMS.

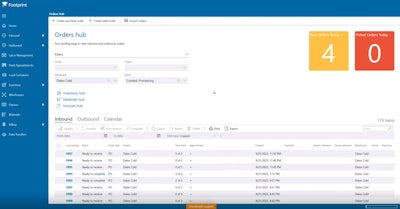

WMS/TMS

Datex Corp.

Datex Corp.

www.datexcorp.com

Name of Solution/Technology: Footprint WMS

Product Description: Datex Footprint WMS is a premier Software-as-a-Service WMS designed to empower cold storage warehouse operators with technology that can accommodate multi-temperature environments. Hosted on Microsoft Azure and fully powered by Datex’s Wavelength low-code application platform, Footprint offers intuitive drag-and-drop simplicity and zero downtime updates. Built for harsh environments, the mobile interface is highly customizable and easy to use, helping cold storage operators to achieve both operational efficiency and simplicity. Benefits include:

Scalability. Scales effortlessly with the growth of the business.

Visibility. Provides complete data transparency and total operational control.

Flexibility. Whether a company needs a simple solution or a complex setup, an intuitive drag-and-drop interface lets users tailor their instance without hassle.

Seamless integration. Footprint connects to critical business and supply chain systems, ensuring streamlined operations and maximum efficiency.

Footprint WMS is seamlessly integrated to other systems, allowing for e-commerce, shipping and manifesting, EDI, and the latest technologies such as flexible automation, AI, and robotics. Footprint’s unique data and technology structure allows better data management, real-time visibility and the ability to meet rapidly changing needs with quick feature updates that don’t require massive system updates. Further, the company’s emphasis on usability during development translates to faster onboarding and intuitive operation by system admins and simplified mobile interface for warehouse associates. Other features entail restriction of inventory to specific temperature zones; stores inventory in primary or secondary locations; provides specific temperature-controlled functionality; enables catch/variable weight; captures temperatures; enables lot control and serialization and excels in managing multiple levels of package serialization and inventory aggregation. It offers detailed identification by genealogy, lot/batch, serial number, unit of measure, disposition, and historical activity trace.

CLICK HERE to learn more about all of our winners.

Here are some additional standouts:

Kaleris

Kaleris

Kaleris

www.kaleris.com

Category: WMS/TMS Software

Name of Solution/Technology: Kaleris TMS + YMS

Product Description: Kaleris TMS + YMS is a comprehensive yard and transportation management solution, created by combining the CAMS Prospero Transportation Management system with the Kaleris yard management system. The former CAMS Prospero TMS, now Kaleris TMS, following Kaleris' acquisition of CAMS Software, manages all aspects of trucking operations for grocery retailers and wholesalers, providing dispatch, backhaul, driver payroll calculation, and vehicle tracking for all inbound, outbound, and return trips. Electronic logging devices (ELDs) in the truck cab provide drivers with complete information for their shift, including destination information, turn-by-turn directions and remote re-dispatch information in the event of real-time changes. The ELD also tracks drivers’ Hours of Service to ensure compliance and for IFTA reporting. The Kaleris yard management system, formerly PINC, optimizes and streamlines yard operations for all types of yards, including finished goods and manufacturing sites. The Kaleris YMS provides real-time tracking and visibility of all assets within the yard, including trailers, containers, and equipment. It automates various yard processes, such as gate check-ins, trailer moves, and dock assignments, reducing manual intervention and improving efficiency. It also facilitates the scheduling and planning of yard activities, ensuring that resources are optimally allocated and operations run smooth.

Luma Brighter Learning

Luma Brighter Learning

Luma Brighter Learning

https://lumabrighterlearning.com

Category: Supply Chain Visibility Solutions

Name of Solution/Technology: Luma Navigator

Product Description: Luma Navigator is an advanced learning tool that harnesses data and multiple interaction types to create individualized coaching plans for each learner. By delivering just-in-time training through multiple types of interaction over a period of time, this technology helps build a meaningful connection between the driver and the driver's manager. Luma Navigator brings in custom data from the fleet, FMCSA data on driver performance, telematic data from the trucks, workman comp data, etc., and then based on performance, assigns coaching plans to each individual, which includes different interaction types that can be automated or manually assigned on a cadence. Fleets can assign any type of AI-generated custom learning or choose one of Luma's 1,300-plus microlessons. Key features include:

Live online synchronous instruction provides real-time, interactive learning experiences that allows for immediate feedback and personalized guidance.

Immersive learning experiences, or 2D learning experiences, create realistic scenarios that enable learners to see an actual environment that is meaningful to the fleet, leading to improved retention and performance.

Motivational surveys help identify individual learners’ goals, challenges, and preferences, allowing for the creation of tailored learning paths that optimize engagement and achievement.

Phone evaluations offer a personalized, one-on-one approach to assessing learners’ progress, providing targeted feedback and coaching that addresses specific areas for improvement, ultimately supporting individual growth and success.

Nulogy

Nulogy

Nulogy

https://nulogy.com

Category: Supply Chain Visibility Solutions

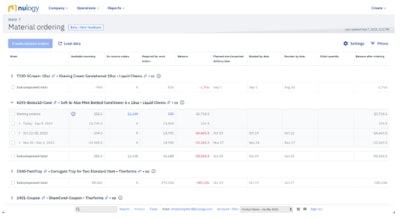

Name of Solution/Technology: Materials Management Capabilities

Product Description: Nulogy introduced new materials management capabilities within its two key products, the Supplier Collaboration Solution (Materials Visibility Module) and the Shop Floor Solution (Materials Ordering Tool), to provide brand owners and their external supply chain partners with the resources needed to reduce material supply risks, ensure continuous operations, and take a collaborative, proactive approach to effective materials management. The Supplier Collaboration Solution’s Materials Visibility Module is a materials monitoring report that can show the impact of material shortages on demand. This module provides a real-time view into the impact of material shortages and enables brands to proactively work with customers or suppliers to resolve potential issues. As a shared view, the data is available to both brands and external supply chain partners to enable rapid alignment and corrective action. The Shop Floor Solution’s Material Ordering Tool streamlines and simplifies material ordering processes. It combines information on current inventory levels, receive orders, work orders, and bill of materials to identify expected material deficits and provide material planners with all relevant information to make optimal material order decisions. Additional features and benefits include efficient material shortage identification, timely order recommendations and streamlined order creation.

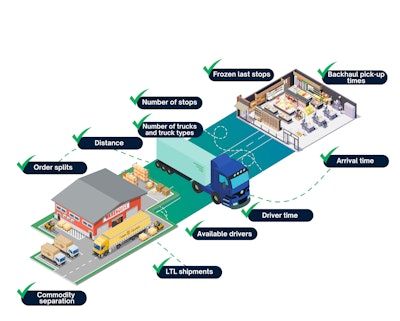

ORTEC

ORTEC

ORTEC

www.ortec.com

Category: Supply Chain Visibility Solutions

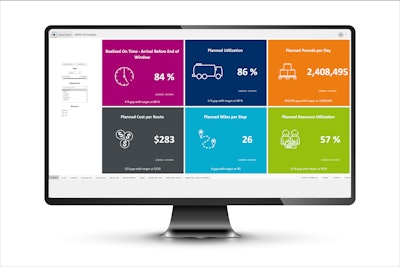

Name of Solution/Technology: ORTEC Load Building and Final Mile Optimization Suite

Product Description: ORTEC Load Building and Final Mile Optimization Suite is tailored to meet the specific needs of companies operating in the supply chain and wholesale delivery sectors. This suite of tools is designed to optimize load building processes and streamline final-mile delivery operations. Enhanced features include:

Dynamic load building. Leveraging advanced algorithms, the suite enables dynamic load building to create optimal load plans that account for various constraints, including vehicle capacity, delivery time windows, and product compatibility.

Multi-stop consolidation. Companies can consolidate multiple orders into efficient routes, minimizing the number of vehicles required for delivery and reducing overall transportation costs.

Real-time adaptability. The system can adapt to real-time changes in orders, vehicle availability, and traffic conditions, ensuring that load building remains optimized in dynamic operating environments.

Final-mile route optimization. The suite provides robust route optimization capabilities to ensure that final-mile deliveries are executed in the most efficient and cost-effective manner, considering factors such as traffic patterns and delivery time windows.

Time slot management. Companies can efficiently manage delivery time slots, allowing for flexible scheduling based on customer preferences and operational constraints.

Dynamic dispatching. Real-time dynamic dispatching capabilities enable adjustments to delivery routes based on changing conditions, ensuring timely and efficient deliveries.

ERP and TMS integration. Seamless integration with enterprise resource planning (ERP) and transportation management systems (TMS) facilitates streamlined data flow and process alignment, enabling end-to-end visibility and control.

Real-time visibility. The suite offers real-time visibility into load building and final-mile operations, empowering companies with actionable insights for proactive decision-making and improved customer communication.

Performance analytics. Robust analytics and reporting capabilities allow companies to track key performance indicators, identify operational bottlenecks, and make data-driven decisions to enhance overall efficiency.

Cost analysis. Organizations can conduct comprehensive cost analyses of load building and final-mile operations, enabling informed resource allocation and cost-saving initiatives.

Operational efficiency. The suite's advanced optimization capabilities drive operational efficiency by minimizing unnecessary miles driven, optimizing resource utilization, and streamlining load building and final mile delivery processes. Real-time visibility and comprehensive analytics empower companies to make informed decisions, identify trends, and continuously improve their load building and final-mile delivery operations, driving sustained business growth and success.

Penske Truck Leasing

Penske Truck Leasing

Penske Truck Leasing

www.gopenske.com

Category: Supply Chain Visibility Solutions

Name of Solution/Technology: Catalyst AI

Product Description: Catalyst AI delivers real-time insights into fleet performance and optimization, and empowers fleet managers to make actionable decisions to optimize fleet performance using dynamic comparative data. The first of its kind in the transportation industry, the platform entails a patent-pending algorithm that identifies the most similar fleets by evaluating key dimensions of fleet operations and composition. This process creates a unique "fleet DNA," enabling highly customized operational KPI benchmarks tailored to each fleet's specific performance needs. Catalyst AI empowers leaders to benchmark their fleets using apples-to-apples comparisons, unlock fuel efficiency opportunities, optimize fleet utilization, and improve business performance using targeted insights.

RTA

RTA

RTA

https://rtafleet.com

Category: Supply Chain Visibility Solutions

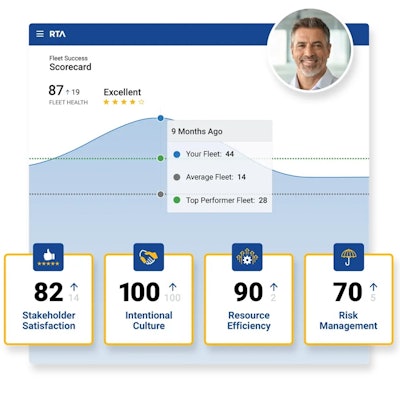

Name of Solution/Technology: Fleet360

Product Description: Fleet360 is an all-in-one fleet maintenance solution, purpose-built for fleet managers and mechanics, and designed to streamline and optimize fleet operations. Fleet360 has evolved to offer more robust tools and functionality, as a fully integrated platform that streamlines every aspect of fleet management. It now offers a more cohesive approach to handling day-to-day operations, making it easier for mechanics to prioritize and track their work and easier for fleet managers to oversee large and complex fleets. Food and beverage teams have the ability to manage every detail of a fleet’s assets, work orders, inspections, preventive maintenance, parts inventory, purchase orders, and fuel expenditure, all summarized in easy-to-use dashboards and reports. Fleet360 also empowers food and beverage businesses to optimize every aspect of their fleet’s operations, ensuring timely deliveries, cost control, and seamless management of assets and resources. Some specific enhancements include:

Fleet Success Scorecard provides real-time performance metrics, allowing fleet managers to track and improve fleet efficiency with data-driven insights and compare their performance to other fleets in their industry.

Guided tours entail step-by-step guides for new users, streamlining onboarding and ensuring efficient use of the system.

Role-based user groups provide customized access levels based on user roles, improving security and workflow efficiency.

RTA Inspect is a streamlined, DOT-compliant inspection tool that allows for faster, more accurate fleet asset evaluations.

Rygen Technologies

Rygen Technologies

Rygen Technologies

www.rygen.com

Category: Supply Chain Visibility Solutions

Name of Solution/Technology: X1 Integrations Platform-as-a-Service (iPaas)

Product Description: X1 is a cloud-native integration engine that empowers users to create and manage integrations faster and more efficiently, decreasing the level of involvement needed from IT resources. With a focus on user experience, X1 increases the speed and value of business integrations while reducing implementation time and cost for supply chain experts. It's AI-enhanced platform allows for data-mapping with effortless diagnostics so users can implement integrations in days, rather than weeks or months. Key benefits are:

Interoperability across disparate systems. X1 supports a wide range of protocols and formats, enabling easy data transformation, and simplifying partner onboarding.

Visibility and traceability of transactions. X1’s document-centric message processing provides a full lineage and audit trail of each transaction. Detailed event logging allows users to quickly identify and resolve bottlenecks.

Speed of integration and deployment. X1 operates without the need for developers or code deployment, thorough AI-assisted configuration, and instant scalability.

VIA Technologies, Inc.

VIA Technologies, Inc.

VIA Technologies, Inc.

https://viatech.ai/forklift-safety-overview

Category: Supply Chain Visibility Solutions

Name of Solution/Technology: VIA Mobile360 Forklift Safety System

Product Description: The VIA Mobile360 Forklift Safety System is a multi-camera safety system that eliminates blind spots and increases visibility around the vehicle. The system's cameras detect pedestrians accurately, delivering precise audio-visual alerts that reduce distractions and prevent collisions. Enhanced features include:

Pedestrian detection. Smart AI cameras accurately detect people approaching the vehicle, minimizing alert fatigue and preventing accidents before they happen. Dual alerts. With a detection range of up to 8 meters, audio and visual alerts deliver timely warnings when pedestrians are detected, which gives operators ample time to react to potential hazards.

Multiple camera configurations. Choose from multiple camera placement configurations with up to three cameras around the vehicle. This allows for flexible detection zone arrangement tailored to the work environment and specific detection needs.

Driver Safety System (DSS). Detects fatigue, smoking, or phone usage, prompting operators to take breaks while fostering a culture of care and safe driving practices. VIA Mobile360 Forklift Safety System eliminates blind spots, increases situational awareness, simplifies fleet management, improves operator training and strengthens safety protocols. To further improve workplace safety, additional features entail vCare, a cloud-based online platform that provides fleet operations data, driver information, and safety analytics such as vehicle usage and alert rates with a 24-hour trend chart. The system automatically records video footage of each alert event, and configures work areas to track vehicle status and receive alerts when vehicles enter or exit designated zones. Additional features include Seatbelt Sensor, which detects whether the driver’s seatbelt is fastened or not, and Wireless Speed Sensor, which tracks vehicle speed and direction to ensure each alert is accurate and necessary.